Substituting pyrolysis oil for fossil fuel can be already be done today by medium or large-scale (co-)combustion of natural gas, coal or heating oil fired boilers, furnaces and turbines.

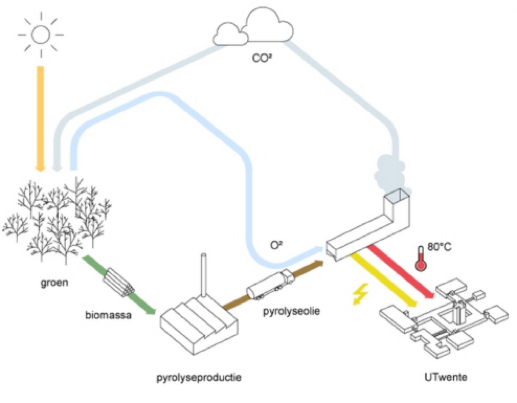

Retrofitting these systems requires limited investments and due to its GHG savings of around 90% pyrolysis oil offers a unique opportunity to make your energy supply more sustainable while also reducing your dependency on fossil fuel prices. Even more interesting is its use in decentralized CHP solutions found for instance in district heating or at large industrial companies who produce their own electricity, heat and/or steam.

By direct combustion in a boiler or furnace pyrolysis oil can be used to produce heat. This is the most simple and straightforward application. In this application pyrolysis oil can replace natural gas and heavy and light fuel oils, reducing the carbon emissions by around 90%.

Various manufacturers can now guarantee the performance when using pyrolysis oil on their burner, such as Dreizler in Germany and Stork Thermeq in the Netherlands. The boiler burner needs to be replaced by a multi-fuel burner so that pyrolysis oil can be mixed with natural gas/heating oil, and the pipes and storage tank need to be furnished from stainless steel (the boiler itself does not need to be replaced). The multi-fuel burner offers full flexibility so it can operate on 100% fossil fuels, should there be no pyrolysis oil available.

By replacing natural gas with renewable pyrolysis oil from the Empyro plant on the FrieslandCampina milk powder production site in Borculo it’s direct carbon emissions have dropped by 15 percent. Each year 10 million m³ of natural gas are saved, which is equivalent to the consumption of 8,000 Dutch households.

This application offers companies the possibility to shift (fully or partly) from natural gas, LPG or heating oil to a renewable alternative fuel. Pyrolysis oil is competitive with the price of heating oil. Pyrolysis oil is not competitive with the current low prices for natural gas in most of Europe and the USA. In countries like Sweden (carbon tax), Finland and Brazil with low biomass prices and a higher price for fossil fuels pyrolysis oil can compete on price. Furthermore, an increasing number of countries use incentives (or mandates for advanced biofuels) for pyrolysis oil to replace fossil fuels (SDE+ in the Netherlands, Renewable Heat Incentive in the UK etc.) in order to bridge the price gap and in Europe switching to pyrolysis oil will also yield a significant amount of ETS carbon credits.

If your company is using natural gas, LPG or heating oil for their boiler to produce steam or hot water for industrial processes or (district) heating and you are looking for a green alternative then please feel free to contact us for more information.

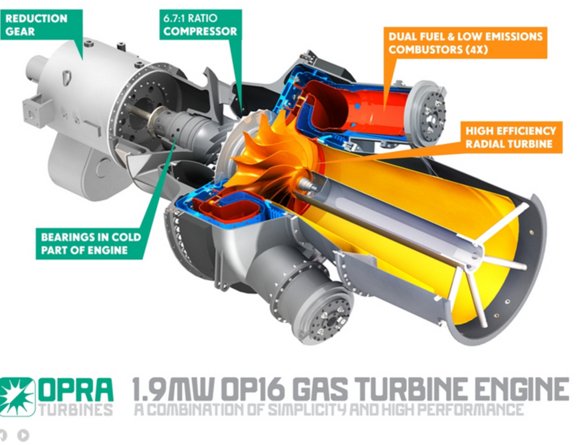

Gas turbines can be used to produce electricity and heat (CHP), for example at remote locations. OPRA turbines in Hengelo provides gas turbine generating sets for customers around the world within the oil & gas, industrial, commercial and marine sectors. Recently OPRA’s 2 MW class OP16 gas turbine has been adapted to run on pyrolysis oil.

The OP16 is of an industrial, all-radial design which provides robustness, reliability, highest efficiency in class and ultra-low emissions. After an extensive series of tests and some modifications to the combustion chamber OPRA can now deliver these turbines with the guarantee that they will run smoothly on BTG-BTL’s pyrolysis oil. This opens up the possibility today to produce 100% green heat and power at any location.

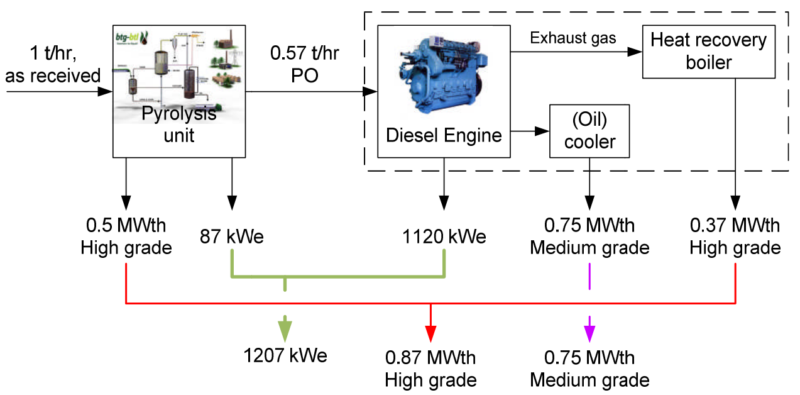

In many areas in the world diesel and natural gas are still being used for diesel engines to produce power and heat. If in these areas biomass is available the pyrolysis oil can be made locally and used locally to produce power and heat. Another interesting application is ship propulsion. In this field the application of pyrolysis oil is one of the few alternatives to fossil fuels that are commercially attractive. Pyrolysis oil has been tested successfully on stationary diesel engines. Some changes to the engines are required, mainly to prevent damage to the engine and fuel system due to water content and acidity of pyrolysis oil. The electrical efficiency is very high for diesel engines (>40%) compared to all other decentralized

alternatives, including gas turbines and the direct burning of biomass to produce power.

We expect the market introduction of diesel engines that can operate on pyrolysis oil in the coming years. This opens up a large new market for the sale of pyrolysis oil as these engines can be used both on ships as for heat and power applications. Pyrolysis oil can be produced on a price level which is competitive with that of diesel. In situations where currently diesel or heavy fuel oil is used pyrolysis oil will be the most attractive sustainable alternative.